Choosing the Right Label: A Quick Guide to the Basics

Labels might seem simple: print, peel, stick, done, but the type of label you choose can make or break how well your product, package, or pallet performs in the real world. Different environments, applications, and regulations call for different materials, adhesives, and printing methods.

Here’s a high-level overview of the most common label categories and where they shine.

Direct Thermal Labels

- How they work: Printed using heat-sensitive material, no ribbon required.

- Best for: Short-term applications like shipping labels, receipts, and temporary tags.

- Considerations: They’ll fade over time, especially with heat, light, or friction.

Thermal Transfer Labels

- How they work: Uses a ribbon to transfer ink onto the label surface, creating a durable print.

- Best for: Long-term labeling, product ID tags, and harsh environments.

- Considerations: Requires a ribbon, but delivers a longer lifespan and more material options.

Freezer-Grade Labels

- How they work: Built with special adhesives that bond even in extreme cold.

- Best for: Frozen foods, pharmaceuticals, and cold storage inventory.

- Considerations: Standard labels can fail in cold, freezer-grade ensures adhesion at low temps and during freeze/thaw cycles.

Food-Safe Labels

- How they work: Made with materials and adhesives that meet FDA or other regulatory requirements for direct or indirect food contact.

- Best for: Food packaging, fresh produce, and ready-to-eat items.

- Considerations: Compliance is key, choose the correct safety certification for your application.

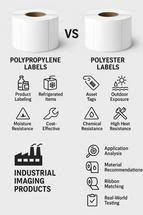

Specialty & Durable Labels

- Examples: Chemical-resistant, tamper-evident, outdoor-rated, or high-heat labels.

- Best for: Industrial, regulatory, or extreme-environment needs.

- Considerations: Designed for specific challenges, know the exposure and compliance requirements before selecting.

Why Industrial Imaging Products Is Your Label Partner

Choosing the right label isn’t just about picking the right material, it’s about making sure it performs in your exact application. At Industrial Imaging Products, we:

- Ask the right questions about your environment, workflow, and compliance needs.

- Test and verify label materials and adhesives before you commit.

- Match labels to your hardware so you get consistent, reliable print quality.

- Leverage decades of industry expertise to prevent costly missteps.

Whether it’s extreme cold, food safety regulations, high-speed production, or tough outdoor conditions, we know how to engineer a labeling solution that will last.

Stay tuned, over the next few months, we’ll dig deeper into each of these label types, sharing when to use them, how they’re made, and the common pitfalls to avoid.

Recent Posts

Jan 5th 2026

Q1 Planning and Purchasing: Building Reliable AIDC Operations

Dec 15th 2025

What Makes a Label Food-Safe? A Simple Guide to Doing It Right

Dec 1st 2025