In manufacturing and industrial sectors, supply chains are the backbone of productivity. Every component, material, and service feeds into a complex system that must deliver on time, at scale, and with consistent quality. A single disruption can have ripple effects across production lines, order fulfillment, and customer satisfaction. For this reason, businesses that balance both domestic and international sourcing strategies gain resilience, flexibility, and competitive advantage.

Why Sourcing Diversity Matters

Manufacturing supply chains are increasingly global. International partners provide access to lower-cost materials, specialized capabilities, and expanded production capacity. At the same time, domestic sources offer proximity, reliability, and faster response times. Businesses that rely exclusively on one or the other expose themselves to risks that can compromise operations. A diversified approach helps mitigate those risks and supports stronger performance over time.

Benefits of Domestic Sources

Domestic suppliers bring stability to supply chain operations. Proximity reduces transit times and shipping costs, while also lowering the risk of delays caused by customs clearance, port congestion, or international trade disputes. Domestic sourcing often allows manufacturers to maintain leaner inventories and respond quickly to sudden changes in demand.

Domestic partnerships also provide opportunities for closer collaboration, improved oversight, and compliance with local regulations. For industries where quality assurance and traceability are non-negotiable, having suppliers closer to home strengthens control and accountability.

Benefits of International Sources

International sourcing expands the range of options available to industrial businesses. It enables access to specialized manufacturing processes, raw materials, or components that may not be available domestically. Global suppliers often provide cost efficiencies due to economies of scale, lower labor costs, or established expertise in specific industries.

By integrating international partners, manufacturers can increase production capacity, diversify risk across regions, and build stronger networks that support growth into new markets.

Balancing Domestic and International Supply Chains

For manufacturing and industrial companies, the most effective strategy is not choosing between domestic or international sourcing, but integrating both into a balanced model. This dual approach provides:

- Risk Mitigation: If geopolitical issues, natural disasters, or labor strikes affect one region, alternative suppliers can keep production running.

- Cost Efficiency: International sources help control costs, while domestic sources limit freight expenses and shorten lead times.

- Flexibility: A broader supplier base enables faster adaptation to fluctuations in demand or disruptions in supply.

- Sustainability and Compliance: Domestic sourcing often supports regulatory alignment and sustainability goals, while international partners help meet scale requirements.

Conclusion

In today’s manufacturing and industrial sectors, a resilient supply chain is a competitive advantage. Relying solely on domestic or international partners creates vulnerabilities that can disrupt operations, inflate costs, and weaken customer relationships. By maintaining a balanced mix of both, businesses can strengthen their resilience, reduce risk, and ensure they are prepared to adapt to the evolving demands of global markets.

For industrial leaders, the path forward is clear: diversify sourcing strategies to build supply chains that are not only efficient, but also agile, stable, and prepared for the unexpected.

Recent Posts

Dec 1st 2025

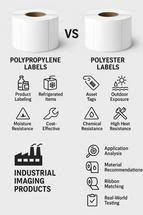

Understanding Poly Labels: Polypropylene vs Polyester (and How to Choose the Right One)

Nov 24th 2025

The Importance of Mobile Device Management (MDM) in Distribution Operations

Nov 17th 2025