Introduction

In high-volume distribution environments, thermal transfer printers are the unsung heroes. They generate the barcodes and labels that keep goods moving, from receiving and put-away to picking, packing, and shipping. Yet, despite their critical role, printers are often overlooked until they fail. By then, downtime has already impacted productivity, accuracy, and customer satisfaction. Preventative maintenance is the answer.

Minimizing Downtime

Every minute of unplanned printer downtime creates a ripple effect: stalled production lines, delayed shipments, and frustrated employees. Preventative maintenance dramatically reduces these risks.

-

Scheduled Cleanings: Regular cleaning of printheads, platen rollers, and sensors extends equipment life.

-

Part Replacement: Identifying and replacing worn components before failure ensures continuous uptime.

-

Proactive Monitoring: Health checks catch early warning signs, avoiding last-minute scrambles.

Improving Print Quality

Unreadable or inconsistent barcodes are more than an inconvenience, they can bring warehouse operations to a halt. Preventative maintenance ensures labels remain crisp, scannable, and compliant.

-

Reduced Reprints: Prevents wasted labels, ribbon, and labor costs tied to poor print quality.

-

Compliance Assurance: Maintains barcode readability to meet retailer and regulatory standards.

-

Consistent Branding: Keeps logos, text, and graphics sharp and professional.

Extending Equipment Lifespan

Printers are a capital investment, and extending their lifespan is a direct boost to ROI. Preventative maintenance helps delay the need for costly replacements.

-

Printhead Preservation: Proper cleaning prevents debris buildup that causes scratches and premature failures.

-

Lower Total Cost of Ownership: Fewer emergency repairs and replacements mean less budget strain.

-

Optimized Performance: Maintains speed and accuracy at designed specifications.

Enhancing Productivity & Employee Morale

When printers fail, operators are forced to improvise, whether by hand-labeling, waiting for IT, or rerouting work. Preventative maintenance helps keep workflows smooth and employees focused.

-

Reduced Bottlenecks: Fewer breakdowns keep throughput on schedule.

-

Streamlined Operations: Devices are kept ready to support peak loads during seasonal demand.

-

Employee Confidence: Workers trust the tools provided, boosting morale and efficiency.

Partnering for Success

Preventative maintenance is more than an IT initiative, it’s an operational strategy. Partnering with a knowledgeable provider ensures your printers are serviced by experts who understand the unique demands of distribution.

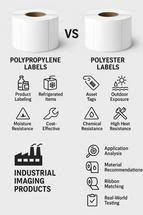

Industrial Imaging Products offers tailored maintenance programs designed to maximize uptime, protect your investment, and keep operations flowing. Our “white glove” service means your printers are not only fixed when broken, they’re cared for to avoid breakdowns altogether.

Conclusion

Thermal transfer printers are mission-critical, and neglecting their maintenance is a gamble no distribution center can afford. Preventative maintenance transforms printing from a reactive burden into a proactive advantage, driving uptime, accuracy, and cost savings.

The choice is clear: Take care of your printers today to avoid losing valuable time, money, and trust tomorrow.

Recent Posts

Jan 5th 2026

Q1 Planning and Purchasing: Building Reliable AIDC Operations

Dec 15th 2025

What Makes a Label Food-Safe? A Simple Guide to Doing It Right

Dec 1st 2025